This is an explanation of the creation of a 3D printed bronze sculpture used to create the Andromeda Devorah edition of three sculptures at 62 cm in height with one Artist’s Proof, and two examples of Devorah cast at 99 cm in height.

In this work, traditional ”hand made or “analogue” sculptural methods have been combined with modern digital techniques of sculpting using a 3D sculpting program.

The process begins by creating a sculpture using the same technique that I developed to create all of the sculptures in the Spirits collection. This “analogue” or hand made sculpture is created in wax and then cast using the traditional “lost wax method” of casting. Once the “analogue” sculpture is cast in bronze, a high-resolution digital scan is made. The resulting digital data file of the original sculpture is then modified using a digital 3D sculpting program.

left: original bronze sculpture

right: smaller modified 3D printed and cast sculpture

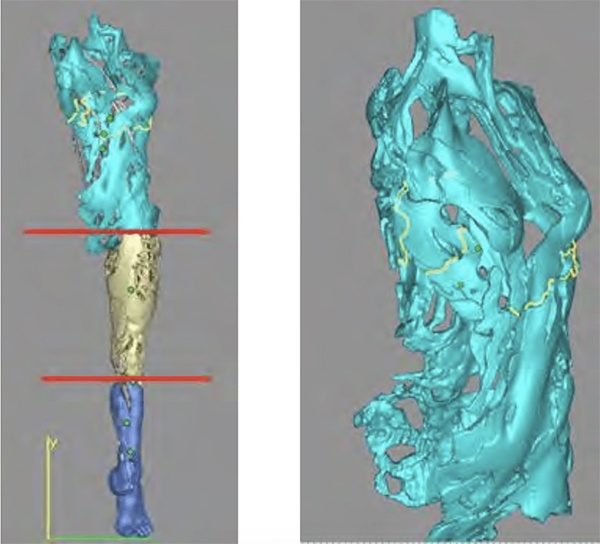

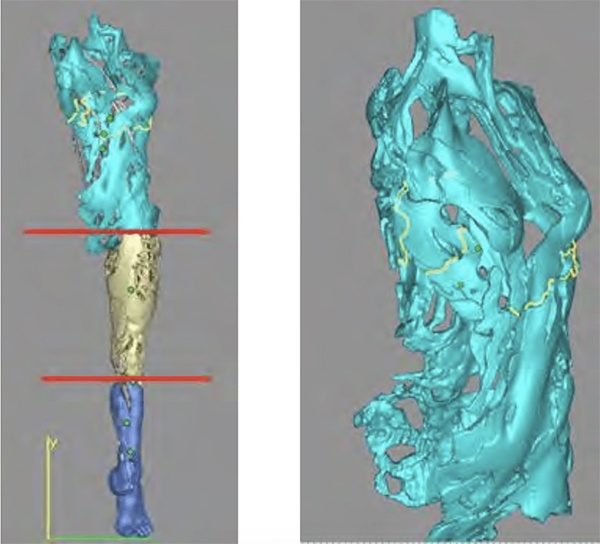

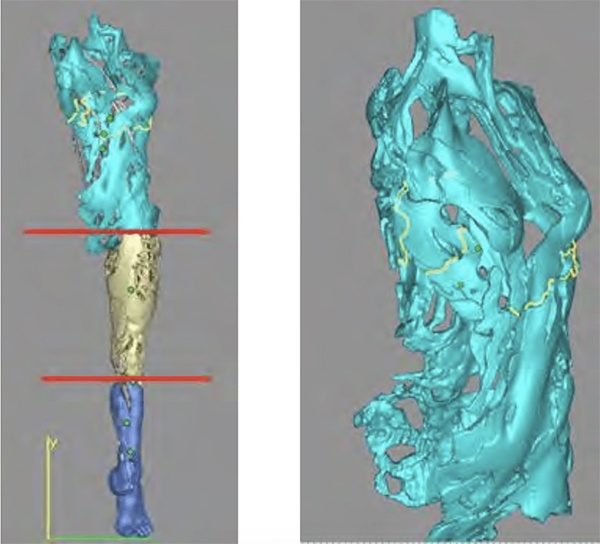

Below are pictures of the scanned data file on the computer, in a software program Zbrush. [1] Note that in the original data file (left) the interior of the sculpture empty. The next step in the process is to create an interior structure inside the scanned digital copy on the computer.

Above on the right is a photograph of the digital sculpture, with the interior structure created digitally with the computer program.

Once the digital file is finished an example of this file is printed on a SLS Printer. Selective Laser Sintering Printing technology uses a laser to bond small grains of plastic and wax based materials into layers in a 3D dimensional structure. The laser traces the pattern of each cross section of the 3D design onto a bed of powder. After one layer is built, the bed lowers and another layer is built on top of the existing layers. The bed then continues to lower until every layer is built and the part is complete.[2]

Below is a photograph of the completed 3D print in a wax polymer specifically designed for casting metal alloys.

The photograph below shows the fist successful test bronze cast with a test 3D printed in transparent plastic.

One of the advantages to 3D printing is the ability to print easily in various sizes. Below is the “bounding box”, indicating the exact size of the print in the three axes in millimetres.

The design for a print of 3 meters in height.

The final bronze cast, show below, was produced at ArtCast Inc., a foundry in Ontario, Canada.

This is 14 inches. (35cm) print of the original sculpture at 87cm. Using this digital technique the sculpture may be cast in an edition of a specific size.

A close up of the finished interior in bronze.

The original “analogue” hand created sculpture Andromeda, the 3D printed bronze Devorah cast from the modified scanned data at 62 cm and the first Test Devorah at 32 cm.

You must be logged in to post a comment.